May 24 2022

iT’s Tissue is, and always has been, all about technology: cutting edge, and experienced in action and close up. It is a unique opportunity. What follows are some of the highlights which visitors can expect when they come to Lucca in June 2022. Here, in the first of our previews, we look at four of the companies behind the project: A.Celli Paper, E80 Group, Futura Converting and Gambini.

A.Celli Paper

A.Celli Paper is an Italian company with 80 years of experience in tissue and paper machinery and equipment. Among the products offered by the company are complete turnkey plants, tissue machines, winders and rewinders for tissue, paper and cardboard, automatic roll handling and packaging systems and Industry 4.0 digital solutions.

With the acquisition of PMT (formerly Beloit) in 2020, the company became the leading player in the sector with 100 percent Italian ownership, extending its range of products and services to the specialty paper, graphic paper and packaging paper industries.

During iT's Tissue 2022 A.Celli Paper will open the doors of its production plant in Tassignano, Lucca. It will be the ideal opportunity for our visitors to experience first-hand a turnkey tissue production line consisting of the iDEAL® tissue machine, E-WIND® winders & rewinders, R-WAY® Integrated solutions for automatic product handling and plant logistics, ending with a focus on Digital Solutions developed to monitor and improve efficiency and effectiveness.

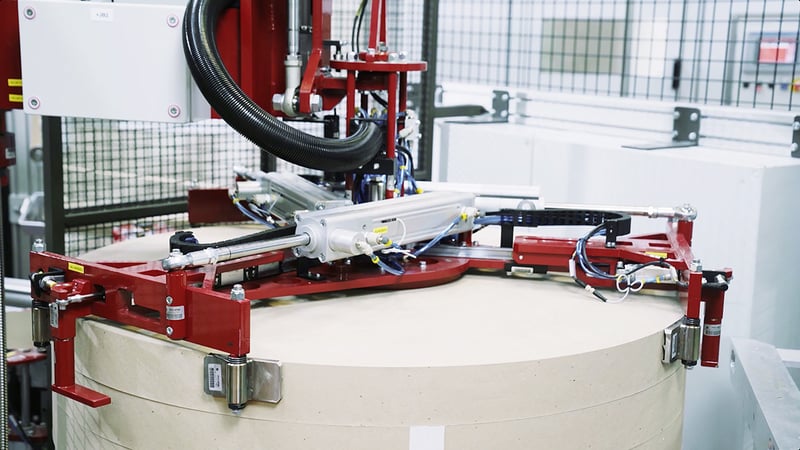

The E-WIND® T200 – part of the E-WIND® winders & rewinders product line which will feature on the line

The E-WIND® T200 – part of the E-WIND® winders & rewinders product line which will feature on the line

which is ready for viewing during A.Celli Paper open house at iT’s Tissue.

E80 Group

Over the years, E80 Group has been developing state-of-the-art technologies that integrate and automate supply chain operations with the primary objective of increasing the efficiency, sustainability and safety of factories and distribution centers in the tissue industry.

Thanks to innovative technologies and a thorough understanding of customers' logistic processes, the Group anticipated the concept of Industry 4.0 back in the 1990s. In addition to hardware systems, E80 Group has developed the SM.I.LE80 (Smart Integrated Logistics) software platform that ensures the integration of systems and flows and guarantees the total traceability of the products handled, from the entry of raw materials right through to shipping.

E80 Group’s end-to-end solutions perfectly integrate all the processes within a tissue plant.

The Group has developed a project in collaboration with Gambini to supply a fully automatic converting line. The two companies will soon introduce a cutting-edge system that brings the parent reel to the rewinder and retrieves the spent core when the operation is finished. All the operations of loading and unloading the jumbo rolls and handling the spent cores inside the unwinder will be automatic, eliminating any hanging paper reels. This fully automated operation will increase line efficiency and operator safety, as it will avoid having reels suspended.

The Smart Tissue Factory – being brought to life with E80.

The Smart Tissue Factory – being brought to life with E80.

Futura Converting

Together with Plusline, Futura will welcome visitors to iT’s Tissue 2022 by presenting the game-changing technological advances the companies have achieved together. It will also be an opportunity to celebrate Futura’s 20 years in business.

Since the last edition of iT’s Tissue, Futura has acquired Plusline and they have already transformed the nature of tissue converting automation and integration, including the development of Together, which receives the logs directly from the rewinder, and generates packaged shelf-ready rolls. The compact layout saves up to 65 percent of space for each line and an provides an unprecedented level of process continuity.

Next the embosser, and with its JOI Hydro-bond Futura has made tissue more sustainable and above all, the embosser area safer.. JOI Hydro-bond allows, even at high production speeds, the perfect adhesion of toilet paper plies with water only, thanks to the exclusive "Zero Deflexion" steel marrying roll, which compresses fibers homogeneously over the entire surface and thus fully exploits the "adhesive power" of water.

Further innovations include: a tail-sealing unit in the rewinder creating a convenient “easy-start” roll; automatic logsaw blade change and grinding; and Camallo – the first automatic solution for loading, unwinding and exchanging coreboard reels. To these we can add new unwinders, able to ensure continuous runnability with a considerable space saving requirement.

These concrete, targeted innovations, are relevant to people’s daily lives and, in the long run, will become the new market standards.

Camallo from Futura – the first automatic solution for loading, unwinding and exchanging coreboard reels.

Camallo from Futura – the first automatic solution for loading, unwinding and exchanging coreboard reels.

Gambini

With 152 years of experience worldwide, Gambini now has 160 employees, divided between three factories, with a fourth to be completed in 2023. Among them is the TissueHub, an R&D center dedicated to the creation of unique tissue products, designed with customers and partners.

In addition, in Wisconsin USA, there is Gambini America, a commercial office dedicated to assistance and spare parts for the North and South American markets.

In June at iT’s Tissue 2022, a G1 line will be shown, complete with packaging, equipped with:

- G1: a rewinder as simple as a mobile phone

- TouchMax: the versatile reference embosser on the market

On the pilot line in TissueHub - the only full-width one - it will also be possible to see an AirMill, Gambini's patented hot roller technology, in operation.

The open house will also feature TMC, Pulsar and Elettric80, which have numerous projects in common with Gambini: one of which - concerning unwinders - will be unveiled during the event.

See G1 and TouchMax among technologies demonstrated at Gambini.

See G1 and TouchMax among technologies demonstrated at Gambini.